Alluvial / Placer / Hard Rock Gold Mining Equipment

Overview Alluvial / Placer / Hard Rock Gold Mining Equipment HZE is the specialist in the field of gold mining processin

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | HZGMP |

| Driving | Electric Motor, Diesel Engine |

| Supply Voltage | 127/220V, 220/380V, 230/400V, 240/415V, 400/690V |

| Gold Recovery Rate | 65-99% |

| Processed Raw Materials | Placer, Alluvial/Eluvial, Hark Rock, Tailings |

| Installation Position | Indoor, Outdoor |

| Warranty period | 550 Days |

| Customization | Acceptable |

| Color | Multi, Selectable |

| Certificate | ISO9001:2015, ISO14004:2015, SGS:QIP-ASR205018 |

| Transport Package | Containerized |

| Specification | Small, Medium, Large Scale |

| Trademark | HZE |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 1000 |

Product Description

Alluvial / Placer / Hard Rock Gold Mining EquipmentHZE is the specialist in the field of gold mining processing and an excellent manufacturer of mining equipment.With advanced technology, perfect technology and processing, reliable equipment and complete services, HZE provides gold recovery solutions that are conducive to environmental friendly and personal health.

APPLICATIONS

In view of occurrence of gold in the different raw materials of placer, alluvial / eluvial deposit, open pit, underground deposit, dump or tailings and allowing for small, medium & large scale of processing, HZE provides different mercury free processes or combination processes and related complete sets of equipment, to recover / extract gold with high efficiency and low cost, and finally produce gold ingots / bullions.

PRODUCTS TYPE

Small Scale Molular Processing Plant

Portable Gold Wash PlantThe coarse and fine particles are completely classified and separated by the trommel. The free gold nuggets and particles existing in undersize slurry are recovered by the centrifugal concentrator and the sluice box then gold is further enriched by the shaking table to obtain the final concentrate. | Small Scale Gold Concentration PlantThe raw materials were comminuted to less than 30 mesh by the supper fine hammer mill, so that the coarse free gold is completely liberated then gold is recovered and enriched by the shaking table to get the concentrate. | Small Scale Gold Processing PlantAfter the raw materials are crushed and milled, the gold is recovered as much as possible by gravity concentration, flotation and other processes to produce concentrate.

| Small Modular Leaching PlantThe slurry after grinding enters the proprietary HZtank to leach gold continuously, and the activated carbon adsorbs gold then the to gold loaded carbon is separated out.

|

PACKAGE SOLUTIONS

According to the actual information of each gold mine deposit and the client's demands, HZE determines the most suitable complete scheme which combining technology, processing , equipment manufacturing, installation, commissioning and on-site training for the client, provides the stage process and equipment as well as the whole plant for the turnkey project. Main process stages and complete sets of equipment include:

Crushing and ScreeningThe open circuit or closed circuit system composed of multi-stage crushers and vibrating screens crushes raw ore to the qualified fine products. According to the customer' requirements, the crushing system can be made into fixed, mobile, modular and other installation forms. | Milling and ClassifyingThe system consists of grinding equipment such as SAG mill, ball mill, and classifying equipment such as hydrocyclone, spiral classifier and vibrating fine screen to grind the ores to the required particle size for separation. | Scrubbing and WashingThe small particles containing nuggets and free gold are fully separated from the big particles by the grizzly, trommel, drum scrubber or vibrating screen.

| Gravity ConcentrationThe multi-stage system consisting of the jig, centrifugal concentrator, sluice box and shaking table recover and enrich nuggets and granular gold at low cost.

|

| FlotationUnder the action of reagent and air in flotation loop, gold bearing mineral particles are collected together to produce concentrate.

| CIP / CILThe slurry is continuously stirred in a group of tanks to leach gold by cyanide or other chemicals, and the gold leached is adsorbed by active carbon countercurrent. The gold loaded carbon is separated and sent to the gold room and the leached tailings are detoxified before discharging. | Loaded Carbon Stripping and ElectrowinningIn the closed unit of high temperature and high pressure, gold loaded in carbon is rapidly stripped out of carbon by eluant and solution becomes pregnant solution which enters the electwowinning cell to precipitate gold dust at a group of cathode plates. | Gold SmeltingThe complete set of gold refining equipment produces alloy gold ingots or to produce gold bullions with purity up to 99.95% and 99.99% according to the client's demand.

|

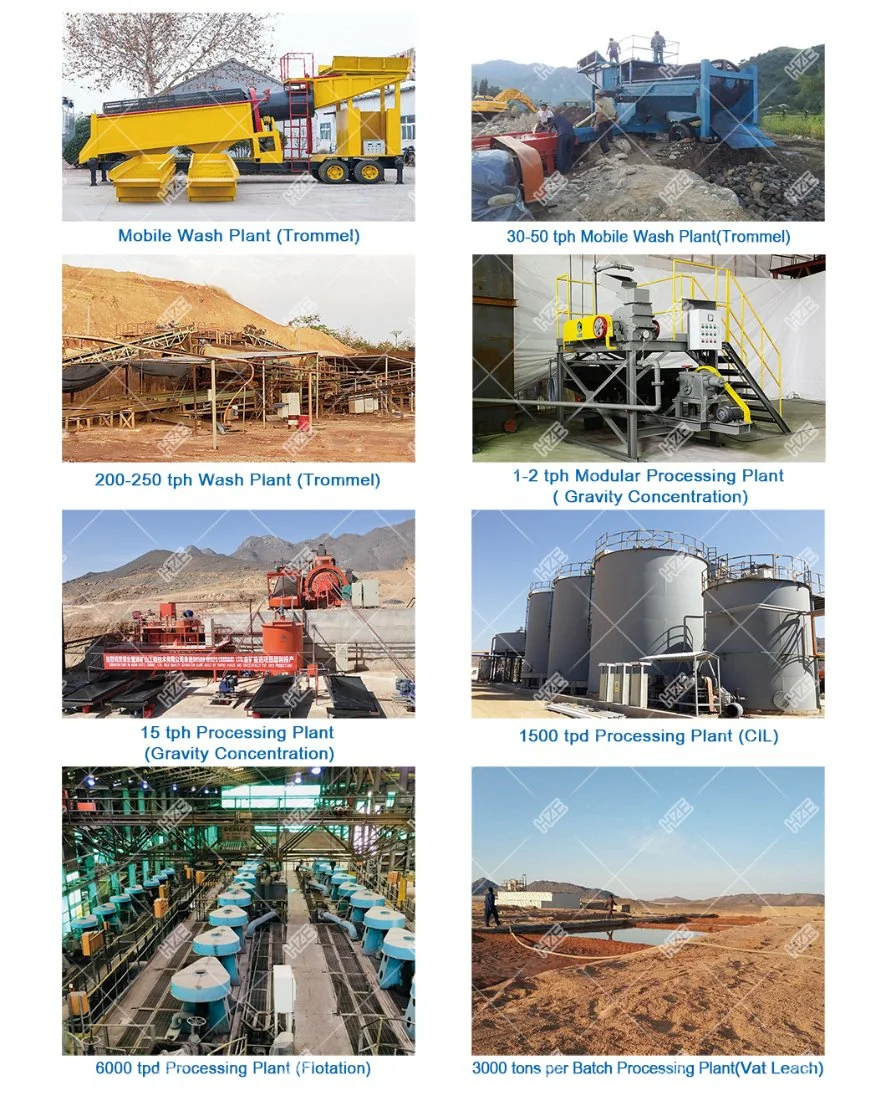

Huize provides small, medium and large scale complete processing plants for customers' different raw materials as follows:

| Plant Type | Capacity Range | Optional Equipment | Applicable Materials |

| Mobile Wash Plant with Trommel | 2-300 tph | Grizzly, Trommel, Vibrating Screen, Sluice Box, Centrifugal Concentrator, Shaking Table, Conveyor | Placer Deposit, Alluvial / Eluvial Deposit |

| Mobile Wash Plant with Drum Scrubber | 30-180 tph | Grizzly, Drum Scrubber, Trommel, Vibrating Screen, Sluice Box, Centrifugal Concentrator, Shaking Table, Conveyor | Alluvial / Eluvial Deposit with Clay or Sticky Materials |

| Fixed Wash Plant | 20-300 tph | Grizzly, Drum Scrubber, Trommel, Vibrating Screen, Sluice Box, Centrifugal Concentrator, Shaking Table, Conveyor | Placer Deposit, Alluvial / Eluvial Deposit, Clay |

| Modular Processing Plant (Gravity) | 0.5-20 tph | Crusher, Hammer Mill, Ball Mill, Jig, Centrifugal Concentrator, Shaking Table, Sluice Box | Hard Rock Ore, Alluvial / Eluvial Deposit |

| Fixed Processing Plant (Gravity) | 10-200 tph | Crusher, Hammer Mill, SAG Mill, Ball Mill, Jig, Centrifugal Concentrator, Shaking Table, Sluice Box | Hard Rock Ore, Alluvial / Eluvial Deposit |

| CIP /CIL Plant | 1-200 tph | Thickener, Leaching Tank, Vibrating Screen, Interstage Screen, Detox Tank | Alluvial / Eluvial Deposit, Clay, Hard Rock Ore, Tailings of Gravity or Flotation, Dump |

| Processing Plant (Flotation) | 1-400 tph | Flotation Cell, Slurry Conditioner Tank, Reagent Dosing Device | Hard Rock Sulfide Ore |

| Heap / Vat Leach Plant | 30-5000 Tons per Batch | Agglomeration Drum, Reagent Dosing Device, Carbon Column, Sprinklers | Alluvial / Eluvial Deposit, Low Grade Ore, Tailings, Dump |

| Crushing Plant | 2-600 tph | Jaw Crusher, Hammer Crusher, Cone Crusher, Vibrating Screen, Conveyor | Hard Rock Ore |

| Milling Plant | 1-400 tph | SAG Mill, Ball Mill, Hydrocyclone, Spiral Classifier, Vibrating Screen | Alluvial / Eluvial Deposit, Clay, Hard Rock Ore, Tailings of Gravity |

| Elution and Electrowinning Unit | 0.1-5 Tons Carbon per Batch | Carbon Column, Electrowinning Cell, Heater, Filter, Acid Wash Tank | Gold Loaded Carbon |

| Merrill-Crowe Process System | Client's Demand | Deoxidization Tower, Zinc Dust Feeder, Vacuum Pump, Precipitation Filter Press | Pregnant Solution Leached |

| Good Room | Client's Demand | Flame Furnace, Induction Furnace, Reactor, Dryer | Concentrate, Semi Finished Gold |

SELECTION AND CUSTOMIZATION

It is welcome that the customer contacts HZE at any time for details of technology, each equipment and processing plant, so as to further understand our technology, products and services.HZE will send the corresponding client questionnaire according to the customer's initial requirements.After receiving the feedback, HZE will give reasonable suggestions, appropriate equipment selection and optimized solutions based on full communication with the customer in order to help the customer to achieve the goals of environmental protection, energy saving, consumption reduction and high profit.

SUPPORTING SERVICES

| Metallurgical TestHZE provides technical support for successful projects by strictly carrying out metallurgical test on the representative mineral samples and determining the optimal scheme. | Engineering DesignHZE adopts three-dimensional software for the whole project engineering design to ensure the smooth implementation of the project and reduce the investment cost. | InstallationEquipment, steel structures, pipelines, electrical and automation, auxiliary facilities are installed on site to form a complete processing plant. |

| CommissioningHZE conducts the plant commissioning to ensure that the productivity and the indicators of production and technical to achieve or exceed the design goals for the best benefits. | TrainingHZE carries out comprehensive training for the customers' employees to ensure that the customers' employees operate the processing plant independently. | EPCAccording to customer demand, with the goal of delivering the whole project, HZE provides one-stop service of engineering, equipment supply and project construction. |

CASES

1.What is the main business scope of your company?

HZE is a company with R&D center, design institute, manufacturing factories, installation and commissioning teams.Our customers are in the mining and mineral processing fields.Our major businesses include mineral processing EPC (engineering, procurement and construction), project consultation, engineering design, mineral processing equipment manufacturing, on-site installation, commissioning, staff training, customer project operation management, spare parts supply and technical support.Customers are free to choose any one or any combination of our services.

2.What are the outstanding advantages of your company?

The one-stop service of mineral processing engineering project and equipment is our core competitiveness.

The most important feature that HZE distinguishes itself from other engineering companies, design companies or consulting companies is that we are also an equipment manufacturer with a production plant of 50,000 square meters, and we have complete manufacturing rout and the related equipment.

HZE distinguishes itself from other equipment manufacturers by owning its own R&D center and engineering design institute.

HZE distinguishes itself from many mining machinery enterprises by possessing an expert team with members including not only senior engineers of the company, but also top Chinese technical experts, university professors and researchers.

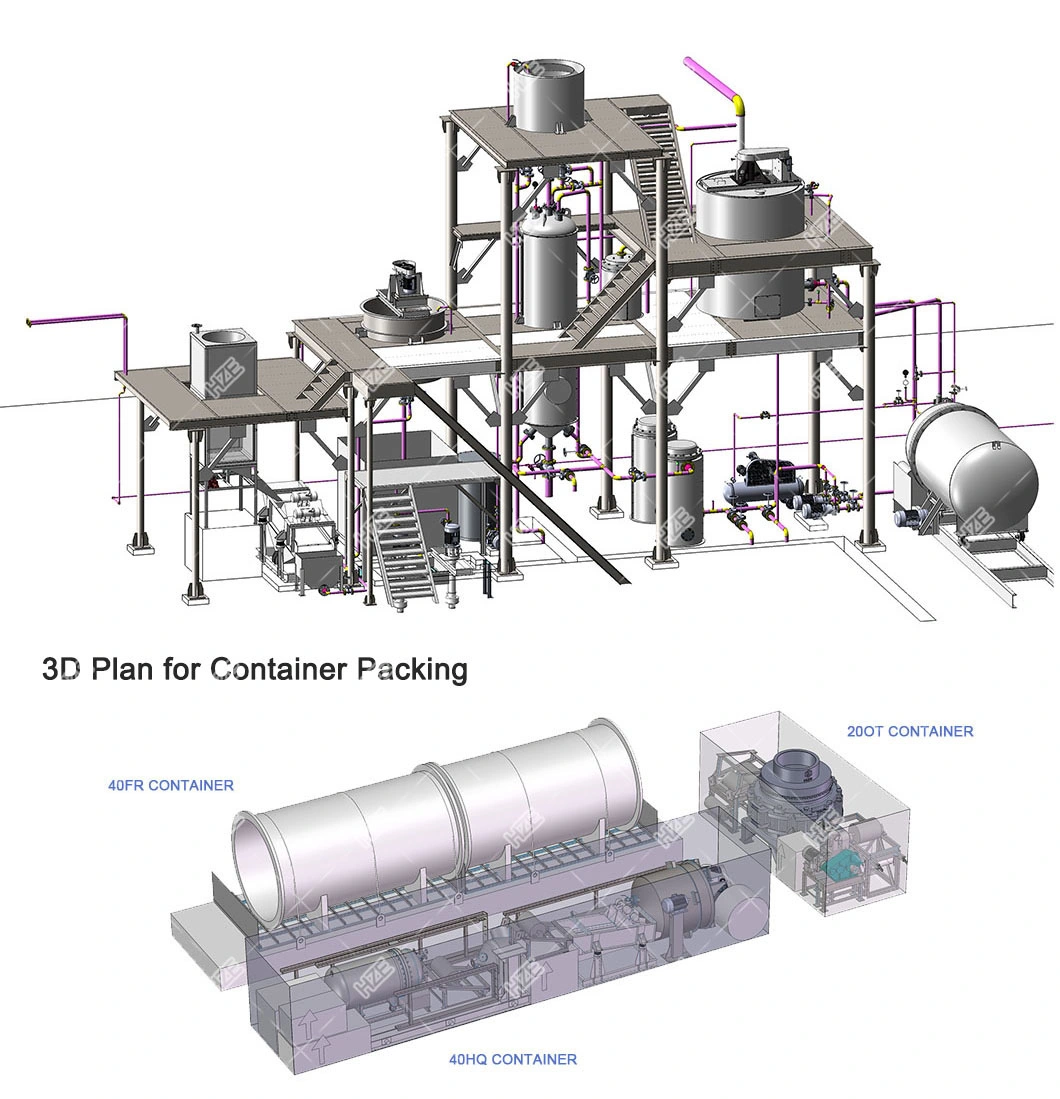

3.What are the characteristics of your company's 3D design?

HZE not only uses 3D software to design equipment, but also uses 3D software to design process flow, pipeline, steel structure, auxiliary facilities, etc.Of the whole mineral processing project.We even use 3D design for equipment packaging, container packing and equipment instructions manual.This greatly improves the quality of equipment and engineering, shortens the construction period, facilitates technical discussion and evaluation, facilitates project management, improves construction safety and reduces project cost.

4.What are the service features of your company?

- Customers who whether buy our equipment, or entrust us with EPC, or require us to provide a certain service, cooperate closely with us to carry out specific operations and supervise our implementation throughout the process.

- HZE will try to understand the basic situation and needs of customers as detailed as possible before the sale, formulate a preliminary plan according to the specific situation of customers, and get unanimous opinions after communications and discussions with customers to determine the plan.

- We set up customer files for every customer who signed the contract with us and upload them to the Cloud where customers can also get an account and password.Customers can have all the documents, videos and pictures, technology, services, execution, operation, management and control, maintenance and so on related to the business.

- Whether it is in the process of general contracting, equipment manufacturing or providing some kind of service, we welcome customers to know about our implementation on the spot or through the network, and put forward requirements and opinions.

- We assist users who have used our products to formulate operation specifications and make suggestions on maintenance plans and spare parts inventories.In addition to routine on-site installation, commissioning and training, during the production period after we handing over equipment to customers for use, we often understand the equipment using situations through the network and provide guidance and training to customer management and operators.

- For the clients who have just start the mining business, we provide the opportunity of training and practice in China's mines for the clients' employees, until they are skilled in operation and maintenance.

Related Products